Manufacturers of Precision Stainless Steel

-

Email

info@goldenmetal.in

-

Location

Maharashtra

-

Location

Maharashtra & Gujarat

Golden Metal Is The Industry Leaders

MANUFACTURERS OF PRECISION STAINLESS STEEL

With a relentless dedication to perfection, we redefine industry standards in stainless steel manufacturing. Our unwavering commitment to quality ensures that every product embodies durability, precision, and excellence.

Who We Are

MANUFACTURERS OF PRECISION STAINLESS STEEL

With a relentless dedication to perfection, we redefine industry standards in stainless steel manufacturing. Our unwavering commitment to quality ensures that every product embodies durability, precision, and excellence.

-

10,000+

TONS ANNUAL PRODUCTION CAPACITY

Established in

1974

Clients Served

500+

No. of Employees

100+

Production Capacity

10000+ MT

Coverage

Worldwide

Certifications

ISO 9001:2015

Why Choose Us?

State-of-the-art Manufacturing Facility

Tailor-made Solutions

Proven Track Record

Products

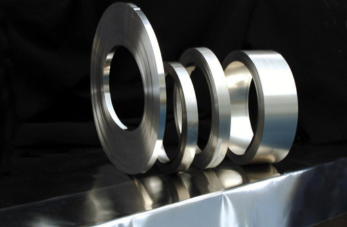

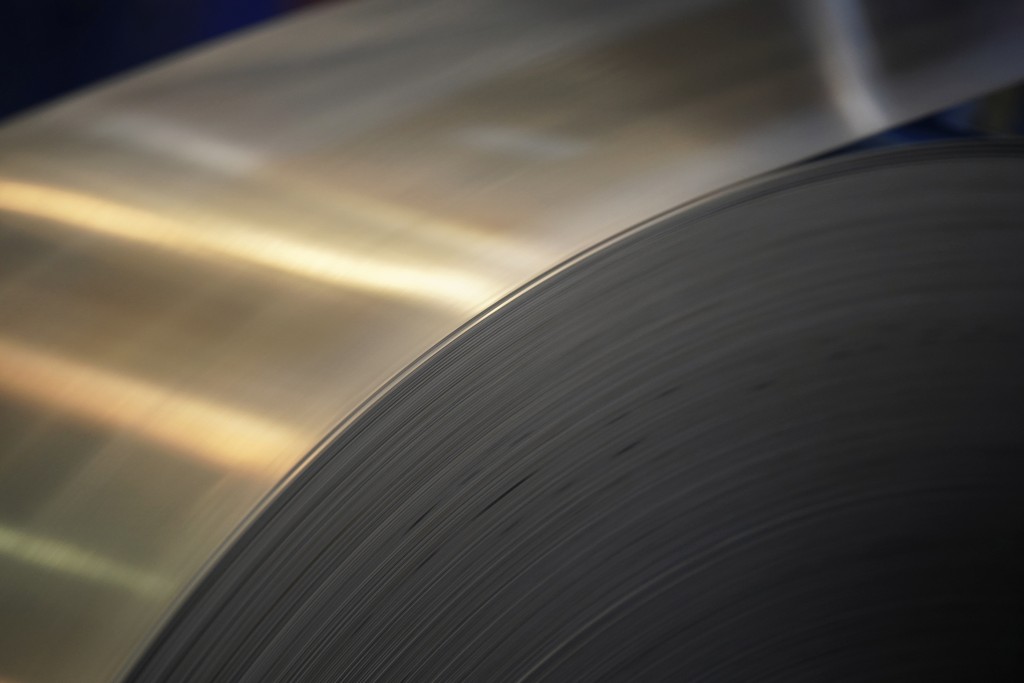

SS Coils and Strips

Discover Versatility and Durability with Stainless Steel Coils and Strips. Precision in Every Coil, Excellence in Every Strip.

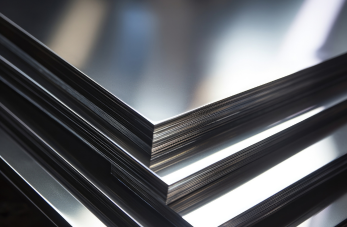

SS Sheets and Plates

Experience the epitome of durability and versatility with our Stainless Steel Sheets and Plates

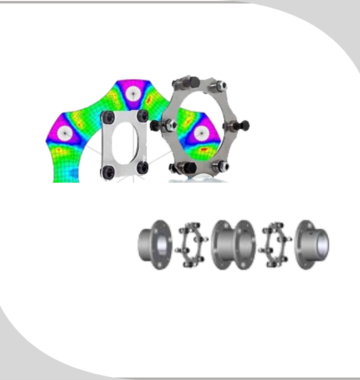

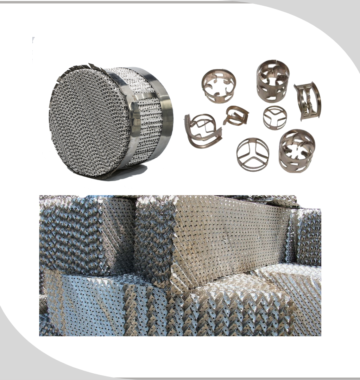

Other Products

Enhance your projects with our premium Stainless Steel products—crafted for durability, precision, and timeless aesthetics

Production Facilities

- Rolling Machines

- Grinding Machines

-

Inspection & Testing

- Slitting & Trimming

- Edging & Oscillation

- Packed Materials

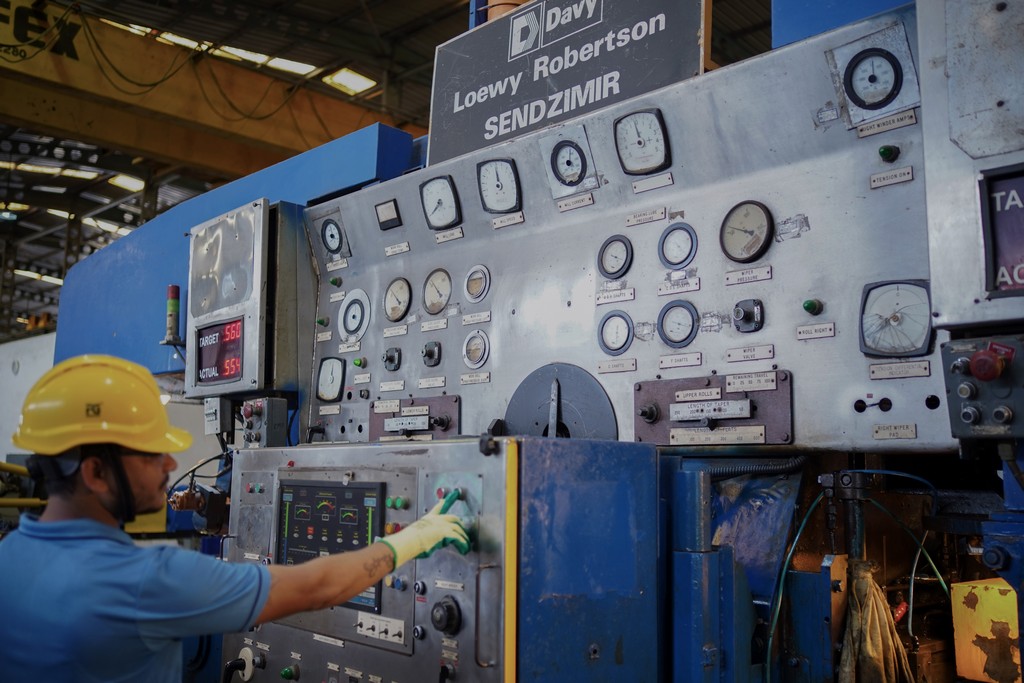

Our Facility is equipped with World class Stainless Steel 20 Hi Sendzimir Cold Rolling Mill (Z Mill Technology) with Automatic Gauge Control manufactured by Davy Loewy Robertson – United Kingdom, ensuring precision and efficiency in cold rolling processes. At GMPL, we are able to roll Cold Roll stainless steel coils from 5mm thickness down to the final thickness of 0.05mm with excellent quality and thickness variation within a maximum range of 3 microns.

These state-of-the-art machine allow us to deliver high-quality, smooth, and consistent metal strips for a variety of industries. With our advanced technology and skilled operators, we meet the demanding requirements of our clients while maintaining the highest standards of quality and productivity.

Roll grinding is an essential process in industries that require precision grinding of metal rolls, such as Rolling Mill Industries. Designed to handle heavy-duty workloads, ensuring long-lasting performance even in harsh environments. With advanced technology, roll grinders provide high accuracy, consistent results, and superior surface finishes during rolling, making them ideal for tasks that demand exacting standards.

They are essential in shaping and smoothing metal coils, strips, or sheets as they move through rolling mills, playing a crucial role in the steel processing industry. By ensuring precision, quality, and efficiency during the rolling process, they have a direct influence on the final steel products.

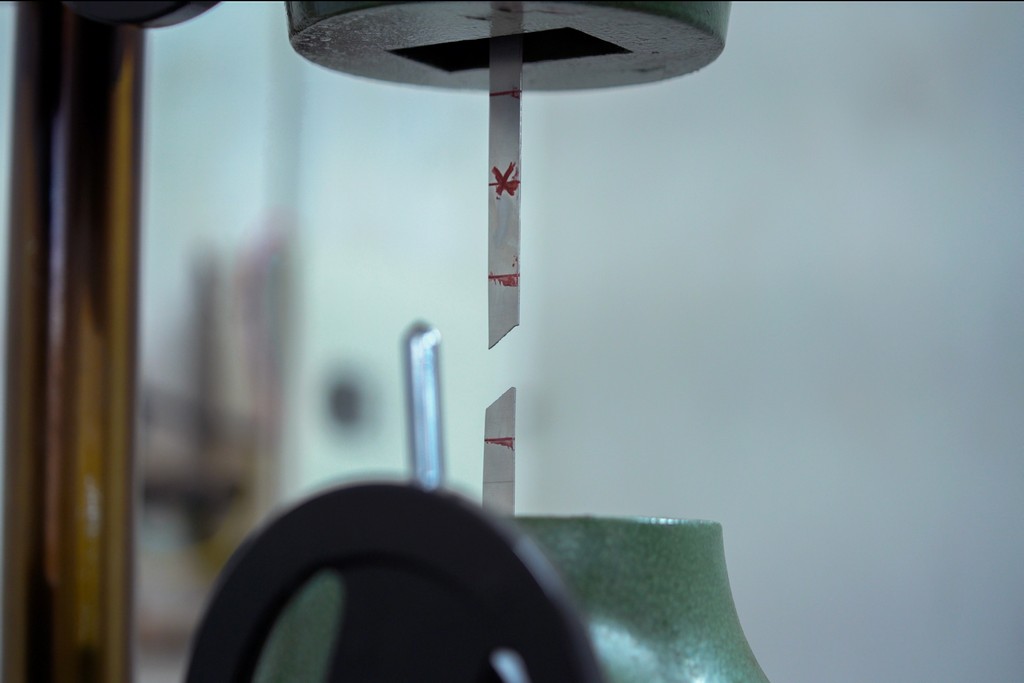

At our manufacturing facility, we prioritize quality through comprehensive inspection and testing at every stage of production. We conduct visual inspections, precise dimensional checks, and surface quality assessments to ensure that our products meet the highest standards. Advanced techniques along with chemical analysis, are used to verify the integrity and composition of each batch, guaranteeing that our stainless steel coils and strips consistently deliver performance and durability. In order to deliver the committed quality, all material from raw material to Finished Goods are inspected and tested before being shipped to the customers. Some of our testing equipment’s include:

- • Micro Hardness Tester & Vickers Hardness Testers

- • Universal testing machine

- • Cup Tester

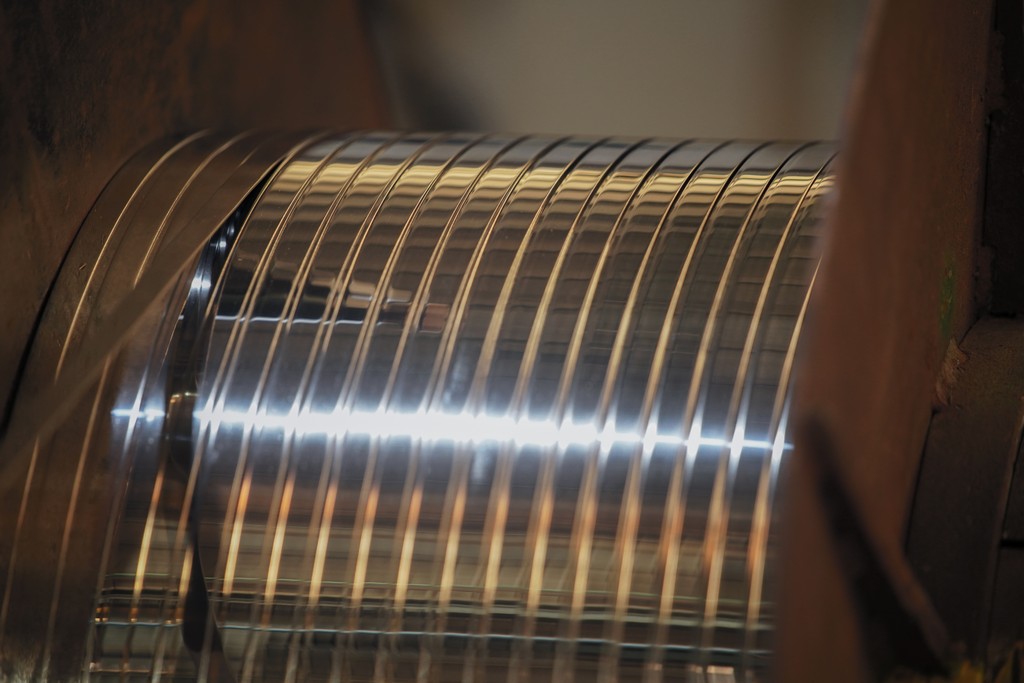

Slitting and Trimming are key steps to ensure precision and customization for our customers. During slitting, wide coils are cut into narrower widths to meet specific size requirements, while trimming removes any excess edges to achieve a clean, smooth finish. These processes are carefully controlled to ensure accurate dimensions, uniformity, and high-quality edges, providing customers with stainless steel products that meet their exact specifications.

We maintain high precision Slitting Lines to maintain the accuracy and burr level. The minimum slit width can be as narrow as 3.20mm.

Edging contours the edge, removes camber, twist and coil set. Conditioned edges are extremely useful in industries where the exposed edges of the strip come in contact with or are handled by processes that require sensitivity. Our edging process smooths and refines the edges of Stainless Steel Coils and Strips, ensuring a clean, uniform finish.

The oscillation process in our stainless steel manufacturing facility involves winding coils in a side-by-side pattern, ensuring uniformity and preventing coil distortion. This technique optimizes coil weight distribution, making handling and transportation more efficient. By maintaining consistent coil structure, oscillation enhances product quality and reduces the risk of damage during storage or shipment. The result is neatly wound, stable coils ready for further processing.

Our packing process ensures that our products are securely wrapped and protected for safe transportation and storage. We use durable materials and specialized techniques to prevent damage, such as rust or deformation, during transit. Each package is carefully labelled with product details for easy identification. This attention to detail guarantees that our products reach customers in perfect condition and ready for use.

Applications